- The stand allows you to store the boom when not in use.

- The stand allows you to transport just the boom to a location without having the boom attached to a fork truck.

- Large tubing was utilized during the design of the stand to allow the operator to keep the forks on the fork truck while hooking up the boom to the fork truck. With the main plate pin in and the mounting plate on the back of the boom. The operator can put the forks of the truck into the tubing, drive forward and as the carriage contacts the main plate he can raise the carriage. When the carriage engages under the main plate the operator can pull the main pin, let the carriage down and the plate will be hanging onto the carriage. At this point the operator can back up the fork truck and install the back plate with the two 1” attachment bolts. The fork truck is now ready to hook up to the boom and lift the boom out of the stand. The operator can drive forward into the boom and put the main pin back in. Using the stand in this manner, no manual lifting of the main plate to install the main plate onto the fork truck carriage is required.

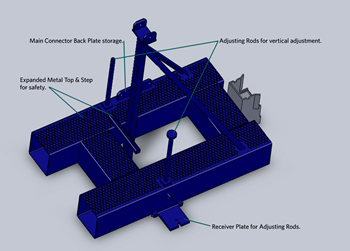

- The stand has a flip down detail allowing the operator to screw the adjusting rods into so as to make the vertical adjustments on the vertical part of the mast. This feature offers more flexibility on the height of the machinery to be rigged.

- Safety tread was added to the entire top of the stand and single step to help keep the operator safe during bad climate weather while hooking or unhooking the boom.

.png)